Quam eligere productio processus de ferro castings?

2024-12-23

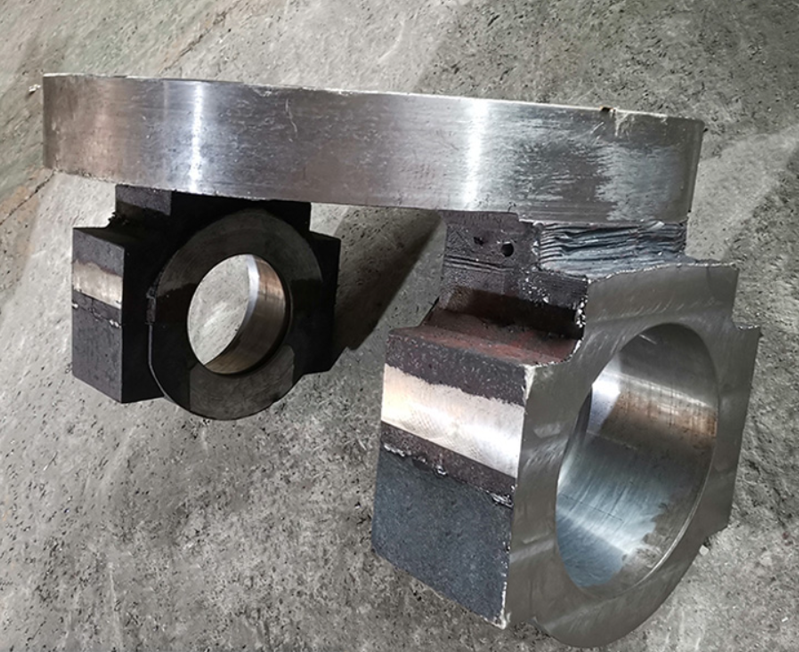

Sicut generalis magnaSteel castingProducts, praeter eius magnitudine et magna forma, murum crassitudo est etiam secundum magnum, ita technicae mensuras perSteel castingManufacturers valde magna.

(I) Frigus ferrum est plerumque dividitur in internum frigus ferrum et externum frigus ferrum, pro crassa partes ut fusum arca et workbench, nos disposuerat per internum frigus ferrum ferrum et foris est locus graphite ferrum et foris est locus graphite frigus ferrum.

(II) et tortor riser est maxime ad densissima pars mittentem super arca archa, et in Vallis Riser diversis specifications potest ludere a valde bonus partes in implerent et recusando, et potest etiam redigendum moles metallum liquida, et potest etiam reducere moles metallum liquida, et potest etiam redigendum moles metallum liquida et potest etiam redigendum moles metallum liquida et potest etiam redigendum moles metallum liquida et potest etiam redigendum moles metallum liquida, et potest etiam reducere moles metallum liquida.

(III) pro alta et magnis castings,Steel castingmanufacturers have designed a total of two sets of pouring systems, the upper one, about one-third of the total height from the upper box, a set of lower and middle areas, the metal liquid will be charged into the pouring system in the lower middle area first, and the pouring system above will be backward, at the same time, the temperature of the metal liquid above is higher than that poured first, so that the pouring system will have a good shrinkage effect on the castings.

(IV) ante initium mittentem,Steel castingNulla fere adopt computatrum simulation technology ad simulare variis preset processus cogitationes pro magna castings, quod potest vitare periculum magnarum castings non probata et tunc produci potest amplio victoria rate magna castings. Nos mos portare ex processu simulation super omnes castings ut qualitas castings.

Traditional metallum formatam industriam, cum continua progressionem scientiae et technology,Steel castingEst etiam constanter integrationem materiae et technologiae ab aliis industries ad consequi suum transformationem et incrementum. In the near future, the composition and properties of raw materials, including scrap, refurnace and pig iron, and the metal liquid formed by a series of reactions that occur during the melting process, will be more clearly understood by more people after filling, cooling, solidification, cooling and other links. In terms of faciens exemplaria, resinae et ferro et aliis materiae et replaced traditional lignum, quae futura progressionem trend et directionem castings, et simul erit a valde magnaSteel castingManufacturers.